Everything You Need to Know About Engine Blocks

The biggest and main component in internal combustion engines is the engine block. This is the stationary metal housing that supports and contains a number of different moving parts responsible for the combustion of fuel and air to produce power. Since it encases the cylinders (as well as the moving pistons inside), it is also called the cylinder block. If you’re completely rebuilding an engine from scratch, this is the foundation to get you started.

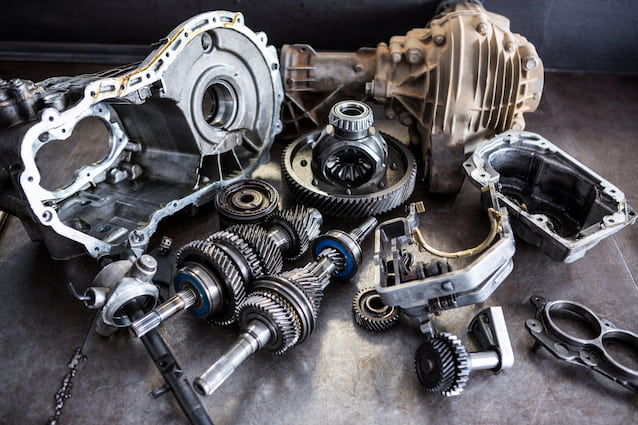

Parts of an Engine Block

The engine block, along with the cylinder head sitting on top, and the crankcase housing the crankshaft right below are the three stationary components in an engine. Their combined role is to serve as a foundation for all moving engine parts. Most current engines have the engine and crankcase integrated into a single unit.

While engines haven’t changed much in over a century, they are still complex feats of engineering, consisting of hundreds of different parts. The same can be said of engine blocks. Here you’ll find the cylinders, an intricate web of oil passageways and galleries, the block deck, and parts like head studs, main caps, core plugs, mounts for the water pump and oil filter, as well as support mounts for the crankcase. Connected to the block are other vital engine parts, such as the alternator, the power steering pump and the starter motor.

The cylinders are where the magic happens. These house the pistons tasked to convert the heat generated in the combustion process into mechanical energy down through the connecting rods and onto the crankshaft. Oil and water passageways are possibly the most interesting, as they serve the secondary function of lubricating the different engine parts and at the same time cooling them. Absorbing and dissipating heat is another crucial role engine blocks have and help with maintaining parts integrity and longevity without compromising engine performance.

The engine block deck is the base for the cylinder head, which includes among other things the inlet and outlet valves and ports and injectors or nozzles depending on fuel type. What separates the cylinder head and the engine block is the head gasket.

Materials and Production Processes

With engines today producing much higher power figures from the same displacement (or size) than just a few years ago, the use of materials and how the engine block is made are crucial factors in how long the engine lasts and how it performs. Traditionally, grey cast iron is used, as it has very high tensile strength and copes with huge temperatures. The weight though is one area it underperforms. This has led to aluminium alloy blocks (mostly mixed with magnesium) which come at half the weight while still being able to push as much power to the wheels without failure. To retain strength, cylinder sleeves in aluminium blocks are made either of steel or cast iron.

Another factor affecting cylinder block strength, and eventually how it does its thing, is the production process. Casting is considered cheap and hence adequate for mass-produced vehicles, but this is where the benefits end. Billet blocks, machined out of a single piece of metal are one technology trickling down to engine builders with a bit more to spend. These are literally works of art and involve meticulous machining, especially in regard to passageways and galleries to improve cooling. While billet blocks don’t add horsepower or torque as such, they’re more in tune with aftermarket modifications like forged pistons and conrods or revised camshafts working with higher loads.

Aftermarket performance blocks additionally have strengthened and thicker cylinder walls, or revised bore and stroke configurations and can endure higher levels of customisation done with cylinder sleeving, boring, grouting and honing to increase block strength as well as produce performance figures an OEM block can only dream of.

Types of Blocks and Engines

Depending on the cylinder configuration within the cylinder block, there are three different engine types – V engines, inline engines and boxer engines. V-engines consist of two rows of cylinders opposed at an angle of 15-20 degrees. Though V8s were the mainstay of legendary Australian cars like the Commodore or Falcon, downsizing due to emissions regulations and fuel use has led to their demise.

Inline engines have cylinders running (as the name implies) in a single line. In-line 6s are a popular engine in bigger luxury and performance cars today, often helped with forced induction. They produce fewer vibrations due to the balanced layout.

Boxer engines are what features in cars such as the Porsche 911 or Subaru WRX and STi. These have two sets of opposing cylinders set at 90 degrees. Engines are balanced, hard-revving and potent. The design is compact, meaning less weight with lighter cranks, and a lower centre of gravity aiding stability.

Common Engine Block Issues

While the engine block is one of the last parts to fail (cylinder heads and head gaskets fail before that), cracked or damaged blocks aren’t a rare occurrence, and entail very high repair bills. The most common reason for a block to fail and crack is overheating. Sustained periods of high temperatures can literally melt the engine. This is when there’s leaking coolant, either from faulty cooling system parts, such as the water pump or radiator, or cracks originating within the block. Further signs that mean the block might be at fault are white smoke, engine knock, gradual or sudden loss of power and rough idling.

Other serious and expensive issues include metal surface contamination, also called porous engine block, often caused by poor production processes and cracked or warped cylinder bore walls. To avoid potential issues, periodically check coolant levels and conduct regular oil changes.