Head Gaskets: How They Keep Your Engine Running Smoothly

Internal combustion engines have hundreds of parts, each with a particular role. Some like pistons and crankshafts are tasked to convert combusted air and fuel into usable power, those like alternators and starters provide the initial spark that gets things going, while others like head gaskets, seal the engine and ensure everything happens as it should. When one part fails, others soon follow, so dealing with engine issues on time with routine inspections is the surest way to avoid costly repairs while still getting the performance you expect.

With that said, if you notice overheating, misfires, rough idling, and white exhaust smoke, chances are you’re dealing with a blown head gasket. This is one of the most stressed engine parts and also one of the most important.

What is a Head Gasket?

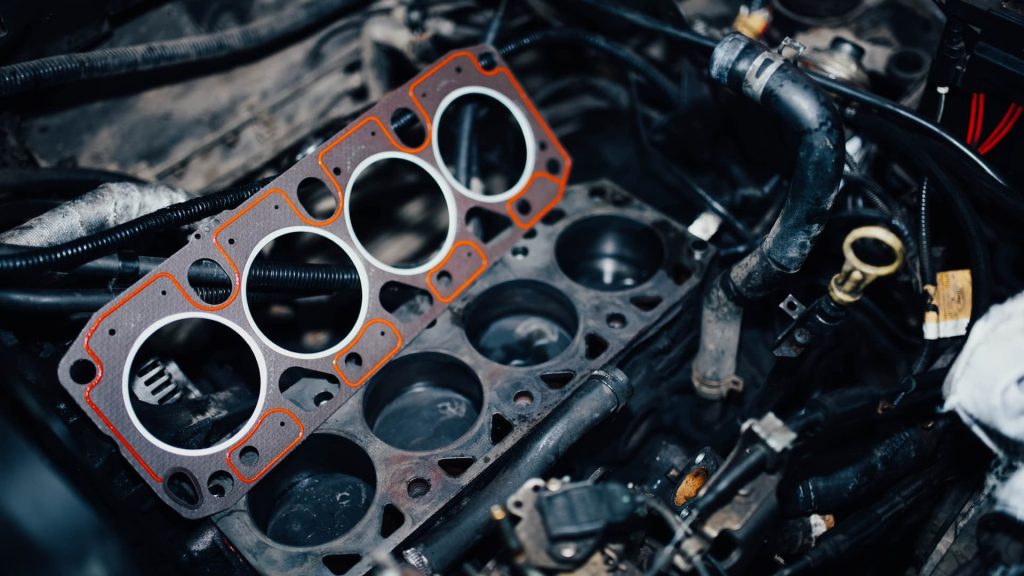

The engine is divided into two basic ‘ends’ – the ‘bottom end’ or engine block, housing the pistons, connecting rods, main bearings and crankshaft; and the ‘top end’ or the cylinder head with parts like the inlet and exhaust valves, spark plugs and camshaft. Sitting squarely between these two engine parts is the engine gasket.

Also referred to as the head gasket, its main purpose is to seal the engine block and cylinder head. This ensures smooth operation and optimal engine power by maintaining the correct compression. It also prevents coolant and oil from leaking into the cylinders while enduring enormous temperatures and the stress of blocks and cylinder heads shrinking, expanding and rubbing against each other.

How Long Do Head Gaskets Last?

In a properly maintained engine (with regular oil and coolant changes), the head gasket should get at least 150 thousand kilometres, before any signs of wear, such as loss of power due to low compression, start to appear. This is in most cases, but the part can fail early on and in newer cars (still under warranty) if there are issues with the engine cooling and ignition systems, incorrect installation, or subpar build quality and inferior design.

Signs of a Bad Head Gasket

Head gaskets can fail in different areas and cause different problems. The first signs of a bad gasket include:

- Coolant and oil leaks – since the part seals oil and coolant passageways between the mated engine components, oil or coolant, or a mixture of the two, around the cylinder head and oil filter points to leaks. Leaked coolant will contaminate the engine oil, and cause increased friction, a rise in engine heat, and advanced parts wear.

- White exhaust smoke and misfires – misfires are caused by off air-to-fuel ratios and skewed compression, largely from damaged gasket seals. The mixture will combust elsewhere (usually in the exhaust) and cause white smoke with a sweet odour, most often accompanied by water vapour.

- Overheating – this can be a symptom of a blown head engine gasket, but also a cause, stemming from faulty parts, particularly stuck thermostats, hose punctures, or radiator issues. Warped and damaged gaskets cause coolant loss, while faulty cooling systems abruptly increase temperatures causing metal fatigue or cracks in the cylinder head or block, preventing proper sealing.

- Pre-ignition and detonation – ignition problems (worn plugs or faulty coils) cause higher temperatures and pressure acting on the gasket, as well as the engine internals. Pre-ignition is when the fuel and air mixture is ignited before the plug fires, while detonation occurs after. Both problems can be disastrous for your engine. If the head gasket is at fault, change it promptly.

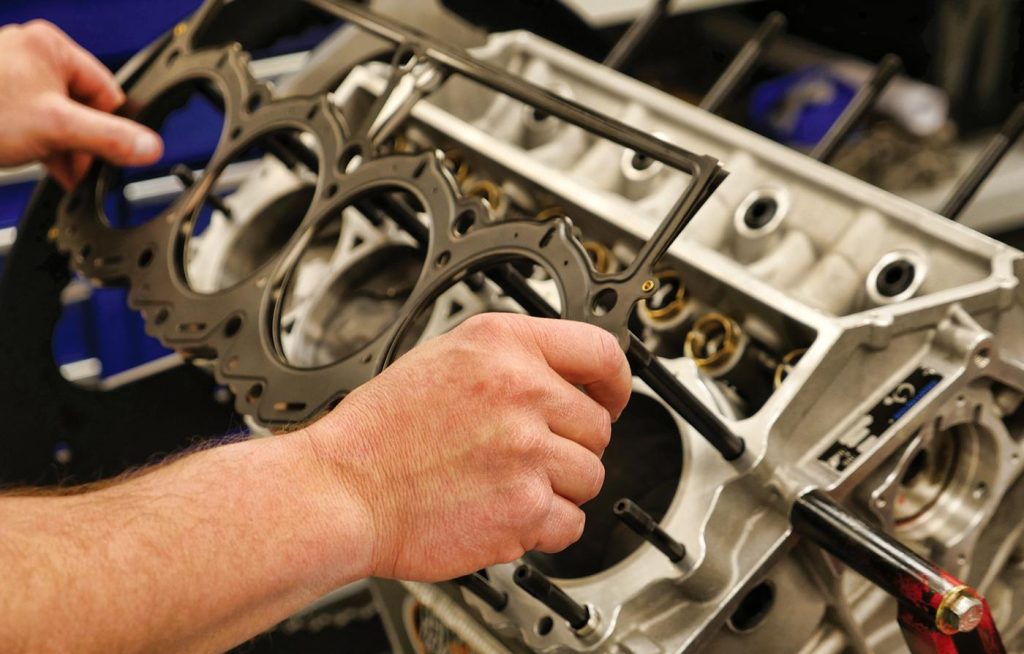

Other causes and symptoms are due to simple wear and tear. All parts wear out including the head gaskets, so observe manufacturer mileage recommendations and get the gasket replaced on time. Additionally, ensure that it is correctly installed. Replacing one is a lot of work, as the engine needs to be dismantled, and checked for damage and surfaces need to be inspected or milled for proper sealing to occur. This can take hours, depending on the condition of the engine. While gaskets are relatively cheap, you’ll be paying more for labour costs, unless you’re qualified or have extensive knowledge to do the work yourself.

Head Gasket Types and Materials

While all automotive gaskets seal different engine and vehicle parts, there’s quite a bit of variety in head gasket materials:

Multi-layer Steel (MLS)

These consist of two to five layers of steel (thus, the name), with the outer layers being embossed or covered in elastomer rubber for better sealing and conforming to surface imperfections, while the centre layer(s) of stainless steel for added durability and better heat conductivity in engines producing more power. MLS gaskets offer longer service life than other materials and better sealing but depend on smoother surfaces to work optimally.

Copper

This was the staple gasket material until MLS arrived. The gaskets are made of solid copper, with steel rings to slot into factory engine O-ring grooves. They have excellent sealing properties and can handle heat expansion in the blocks and head, but may require head and/or block machining in newer car makes.

Composites

Head gaskets in single layers and composite materials, usually graphite, were common until the 1980s. They’re still the cheapest to buy, usually seen in engine rebuilds in older cars, and have good compatibility with rougher metal surfaces. Where the fall behind copper and MLS is durability and lower sealing. They’ve been phased out since today’s production engines rely on higher compression ratios or increased boost pressure to squeeze out more power.

Final Word

Head gaskets are a mirror to general engine health. They seal the engine, let it achieve its rated power, and reduce wear in the engine internals, and cylinder head. Bad or blown gaskets can cause major damage if not caught on time. To ensure your car runs properly, look for replacements compatible with your vehicle.