The Importance of Having the Right Tool for the Job

Cutting, grinding, filing, brushing and polishing are some of the basic activities in getting metal products and surfaces to the perfect finish. So are deburring excess material and rust removal on older pieces. You’ll want the right tool for the job, but also the right attachments. Ones that get the job to a precise finish quickly and easily, with the least fuss. What you’ll ultimately want to avoid is materials and workpieces ruined from sub-par equipment.

Abrasive attachments are necessary pieces in any toolbox, especially for anyone working with metals. The quality of attachments is high, but among a range of different brands, the German tooling specialist Pferd sits high up.

The company began producing hand files well over 200 years ago and has become one of the abrasive tool giants in the business. With over 8500 different products across a wide scope of abrasives, the company now has 8 production sites (3 in Germany alone) with over 2000 employees and distributes its extensive lineup to over 30 countries. Australia is one of the lucky countries on the list, with local offices offering all manners of technical assistance and product training services.

Products from the German toolmaker set the highest benchmarks for product quality and performance in a range of applications and are suited to tradies, fabricators, metal workers, welders, smash repairers, builders, woodworkers and more. All products are OSA (Organisation for the Safety of Grinding Tools) approved, comply with current Australian standards and offer the highest levels of safety.

Considerations for the Best Results

The entire Pferd lineup offers optimal results with tools for the application. This takes into account tool drives and the materials worked on. When combining abrasive attachment tools with the right tool drive (for instance air or electric grinder), take into account the design, shape and size of the tool, the performance and rotational speed it is capable of, and the type of power supply. Also how attachments are mounted will affect end results.

The same applies to materials. Varying material properties put forward different requirements on tools used to work on them. Careful selection, with the assistance of Pferd specialists and retailers, will make any job simple.

Lastly, consider the specifics of the application – what you want to achieve, the working conditions and loads, properties of the workpiece, how long the tool will be in use, and general requirements of workplace safety.

The Pferd Tool Lineup

Files

Starting as a family business way back in1799, Pferd now is an industry leader in all things abrasives. The first tools the company offered were files, and these are what spread the name of Pferd quality the world over. Files offer consistently high cutting performance, ensuring excellent surface quality and long life usage cycles. The company has developed a number of different shapes and cutting profiles in its files, reducing labour-intensive work across a range of industries and crafts.

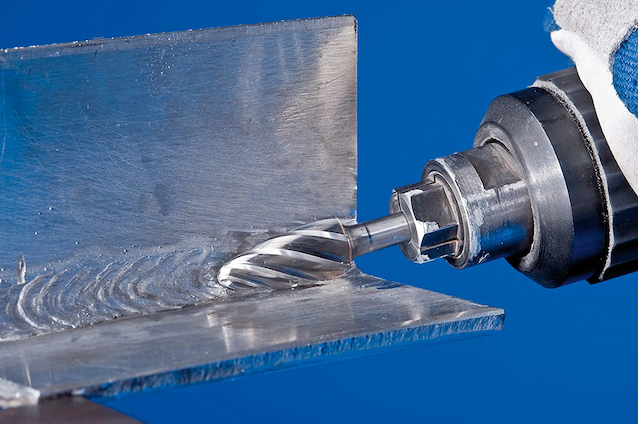

Burrs and Hole Saws

Burrs are used for shaping and machining materials of differing strengths. Pferd burrs have high impact resistance, that prevents tools from chipping and breaking. Strength is increased in the CUT THOUGH and TOUGH-S burr range, ideal in steel fabrication. When working with aluminium and non-ferrous metals, source the Pferd Cut ALU burrs. Other burr lines, like the Cut MICRO, are optimised for high rpm work, and the Cut STEEL for mild steel.

Hole Saws can be optioned in sizes from 16 to 152mm, with the ALUMASTER High-Speed Discs having high removal rates and ideal when working with aluminium, Carbide inserts offer high durability and sustained performance and the hole saws won’t generate hazardous or explosive dust.

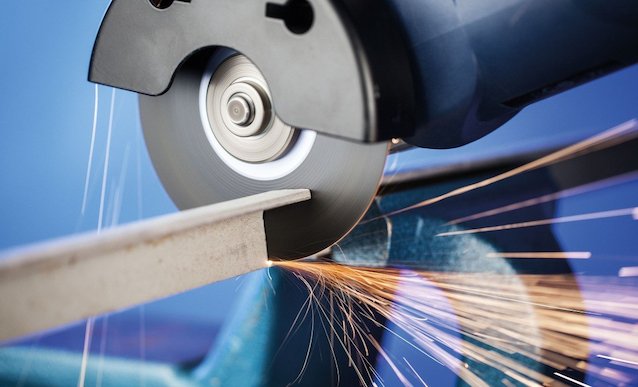

Grinding and Cut-Off Wheels

For rapid stock removal, smoothing out rough welds, grinding edges and removing dust in any application look for Pferd grinding disc and cutoff wheels. Wheels are offered in various sizes and can handle steel, cast iron and workpieces in steely alloys. Cut-off wheels can also work here as well as aluminium and stone. Popular lines like the POLIFAN Flap Discs are ideal for high removal and the newest fibre discs in the ACTIROX range are optimised for efficiency with specially shaped grains. Different mounting options add to the versatility.

Cutting tasks are handled with the company’s large-diameter cut-off wheels working well in both ferrous and non-ferrous metals and hardened alloys and where saws or flame cutters fail. Wheels have self-sharpening, allowing for consistent cuts. Cutting wheels can be had for low and high-speed tools.

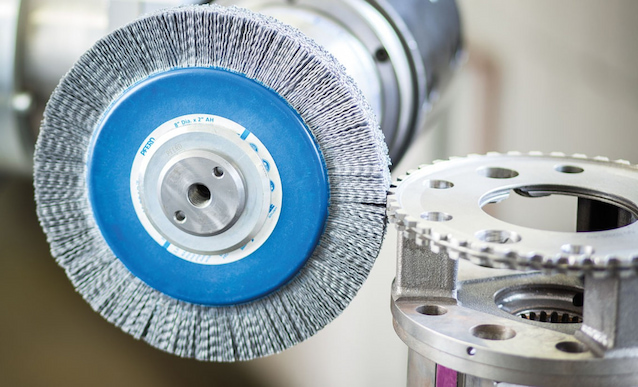

Industrial Brushes

Surface machining is done with the company’s comprehensive range of industrial brushes. These can be used with angle grinders, drills, bench grinders, shaft drives and other rotary tools. Materials in brushes include wire filament (steel, INOX, and brass) and can be crimped for working on contoured pieces, or knotted and with straight wires when working with welds. Plastic filaments mixed with abrasive grains can be with round filaments for brush flexibility or rectangular where aggressiveness is needed. Light cleaning and polishing tasks are done with brushes consisting of natural bristles (or goat hair).

Polishing Tools and Fine Grinding

If you want the perfect finish on any surface, Pferd offers a large range of polishing and fine grinding attachments. Popular tools in the segment include spiral bands, brushed flap wheels, fan grinders, ring wheels as well as pre-packaged polishing kits for various applications. Discs, brushes, bands and drums can be had in a range of materials, have adhesives lining the backing, and be used with a range of air and electric power tools that Pferd have to get the best results.

This vast range also covers tools with specially-formulated synthetic diamond coatings when you need the utmost in strength and durability.