Importance of Picking the Right Industrial Cables: Basic Guide to Cables

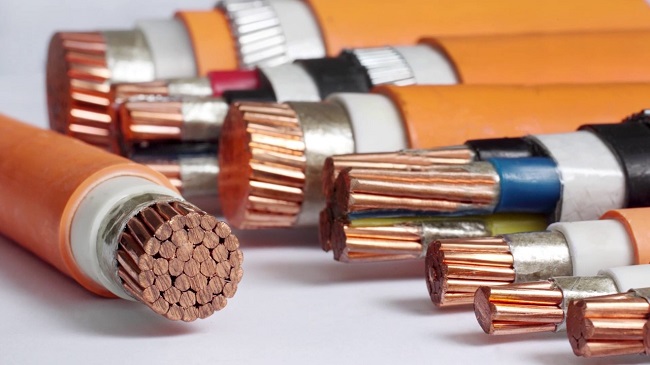

There are almost 3 kilometres of cable running through the average household, and significantly more in the average commercial and industrial facility. While we almost never get to see most of the cables, they power everything so it only makes sense that you should know what the different types of cables and wires are, so that you can pick accordingly and have your equipment, devices and appliances powered properly. But before I delve into the different types of industrial cables, let’s start from the basics – what’s the difference between a cable and a wire? Wires are comprised of a single conductor that carries electrical current through a circuit, whereas cables are comprised of multiple wires that are sheathed together.

Most wire conductors are copper, due to copper’s corrosion-resistant properties and their superior conductivity. Aluminium is also a popular conductor due to being lightweight and affordable. The sizing of wires is measured in AWG (American Wire Gauge), and the higher the number, the smaller the wire. The regulations for cables and wires used for electrical applications are mandated by Standards Australia. Some of the defining features of cables include amperage (measurement for electric current), voltage (difference in electric potential between 2 points), voltage drop (difference between measurements at every terminal of the device) and wattage (electrical energy used).

There are many different types of electrical cables, such as automotive, category, flexible, coaxial, underground residential distribution, service entrance, nonmetallic sheath, mobile home, metal-clad, pendant control cable, etc. Choosing the right type of cable for your residential or commercial application is key to having your devices, equipment and appliances operate properly and safely. If you have any doubt in your ability to choose the right cable or handle an electrical project by yourself safely, it’s best to seek professional assistance.

So how do you identify cables and wires? Every cable has a jacket with information on it to help you choose the right product for your application. The printed letter code provides the attributes of the wire, as well as the gauge, voltage rating, and material. There’s a system that allows you to quickly identify what the cable’s capabilities are; some of the most common letterings include: THHN, THW, XHHW, etc. No matter whether you’re looking for a pendant control cable, a flexible, category, automotive or underground residential retribution, you’ll find these letters and what they represent on the cable’s specification sheet, alongside other characteristics and features of the cable.

The colour of the wires is important in order to be able to easily identify the wire’s purpose. This is not only helpful for the buying process, but for the electricians that are going to be maintaining the electrical system or the advanced DIYer who intends to perform some electrical work on their own. You shouldn’t assume a wire isn’t hot from its colour alone, as all wires have the ability to carry loads and they may be connected differently from the industry standard.

Black wires are typically hot wires for outlets and switches; red wires are typically hot wires for switch legs and connections to hardwired smoke detectors; yellow and blue wires are hot wires pulled through conduit (blue is typically used for four- and three-way switch applications, whereas yellow is typically used for switch legs to lights, control fans, etc); green and bare copper wires are used for grounding purposes, and white is for neutral wires.

There’s another industry standard that applies for nonmetallic colour-coded jackets. They’re similar to how wires are colour-coded, and provide the information for what gauge the wires inside the jacket are. Black jackets represent 8 and lower-gauge wires that are used for electric ranges, subpanels, ovens, etc; orange jackets are 10 gauge wires used for running water heaters and air conditioners; yellow jackets are 12 gauge wires used regularly in households for outlets, general power and most appliances; and white jackets are used for 14 gauge wires that are mainly used for lighting circuits.

When it’s all said and done, the manufacturer behind the cables and wires is also something you need to take into consideration. You want to shop from a manufacturer that has been around for quite some time and has experience and a proven track record of manufacturing quality, reliable cables. You can ensure that by making sure you read through their feedback, most of which should be positive. Once you’ve decided on what vendor you want to deal with, make sure they offer top-notch customer service and are able to answer all of your questions. Lastly, make sure the vendor you go with is a good match for you. In other words, look for a vendor who frequently deals with clients like yourself, and meets all of your needs. That way, they’ll know what you’re looking for and give you suggestions and advice to picking the most suitable cable for your applications.