How Important is Selecting the Right Vibratory Feeder

Vibratory feeders are very important machines in the processing industry, as they efficiently move fine and rough materials from one place to another, or to another machine for further works. In the processing industries, the vibratory feeders accurately transfer materials from the hoppers to a conveyor or to a packing machine. The vibratory feeders are used for many different applications, such as separating, screening, scalping and for removing unneeded products. For different applications, there are different types of vibratory feeders and selecting the right one is crucial for optimal performance.

When choosing a vibratory feeder, many factors need to be considered. You need to specify what kind of material you will use. In general, the vibratory feeders work with three types of materials, including fine, medium and coarse materials. The heavy-duty vibratory feeders are ideal for coarse materials, as they come with larger production capacities, while the light-duty vibratory feeders usually are used for both fine and medium materials. Also, consider the moisture content. Moisture can cause heavy issues in the feeding process, especially if the vibratory feeders are electro-magnetic. Big moisture content can increase the tension on the surface, which can boost the tendency of the material to build up.

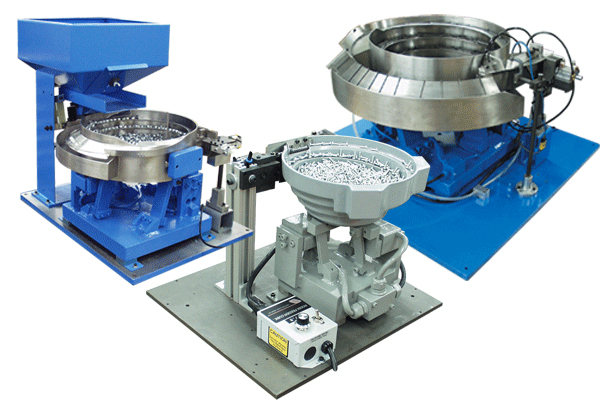

Although they come in different shapes and sizes, and are designed for different applications, all vibratory feeders are consisted of the same components: a drive system that generate vibration, a tray to carry the material, and springs to give the vibration an amplitude while creating motion. The drive systems in the vibratory feeders can be mechanical or electro-magnetic drives. The vibrating feeders usually come with mechanical drives. The mechanical drives come in many different designs, although they all create the same “back-and-forth” motion. The electro-magnetic drives can be operated by either AC or DC power. The AC-operated electro-magnetic drive is accurate and cost-efficient, while the DC-operated drive has many disadvantages and it is not recommended for heavy-duty applications.

When comparing the electro-magnetic and mechanical drives, there are few things that need to be closely considered before selecting the right vibratory feeder. The electro-magnetic drives which are included in many vibratory feeders consume significantly less energy. The mechanical drives on the other hand, are still extensively used in many vibratory feeders for many feeding and conveying applications. With a slow motion in one direction and fast motion in the opposite direction, the mechanical drives are very efficient for fragile materials that are prone to damages.